In this Gerber tutorial, I will teach you how to create the files you need for a 2-layer board using Cadsoft Eagle. After you have completed this tutorial you will have all the necessary files needed to send to most PCB manufacturers.

- Gerber File Types

- How To Open Pcb Gerber File Download

- How To Open Pcb Gerber File Extension

- How To Open Pcb Gerber Files

Right-click a file with the extension whose association you want to change, and then click Open With. In the Open Withdialog box, click the program whith which you want the file to open, or click Browseto locate the program that you want. Select the Always use the selected programto open this kind of file check box. Double click 'Gerber Files' it will open Gerber setup. Use the same steps as above and click ok. Enable output generate option and set target folder location. Clock Run or double click over generates content. The gerber file outputs will be generated. Figure 1: Sample PCB Design file. In figure 1 different layers names are shown in their. A Gerber file opens as project, which can be edited if you want. Add arc, rectangle, polygon, path, and merge polygons. A built-in tool lets you create double sided PCB by inverting layers. It also features a script tool, known as TCL console, which helps users to implement their own features to PCB designs.

This tutorial is out of date. I have switched to KiCad, so I recommend the updated tutorial How to Create Gerber Files in KiCad.

Step 1: Open the CAM Processor

In Eagle, open Board view. Click the “CAM” button or choose “File->CAM Processor”. This will open the CAM Processor tool that is used to generate the files.

Here you can define the sections you want to create files for.

But you don’t really need to understand this. Actually I have never really thought about the details of this until I was writing this article. I have just been using ready-made configurations. And that is probably what you want to do as well.

Step 2: Open a predefined job

To simplify creating Gerber files, Eagle comes with a predefined job for this. It is called gerb274x.cam.

(Note: If you want to order PCBs from Seeed Studio’s Fusion PCB service, you should instead download their own CAM-file from the bottom of their submission guidelines page. Be aware that this will give you different file names than the ones listed below in this article.)

To open it in the CAM Processor click “File->Open->Job…”

Browse to your …/eagle/cam/ folder, and you should see a file called gerb274x.cam. Choose it and click “Open”.

You will now see five tabs in the CAM Processor. Each of these tabs will generate a Gerber file.

Step 3: Adding a second silk screen (Optional)

Gerber File Types

If you look at the tabs, you will see that you don’t have a file for silk screen bottom. For simple boards, the silk screen is usually on the top layer so that you don’t need the bottom. Some of the cheap circuit board manufacturers don’t even allow bottom silk screen.

But if you need silk screen on bottom layer as well, follow these steps:

- Click “Add”

- Change Section to something like “Silk Screen SOL”

- Change File to “%N.pls”

- Deselect all layers

- Select layers 20 “Dimension”, 22 “bPlace” and 26 “bNames”

There you go.

Step 4: Create each gerber file

Select where you want to put the Gerber files by clicking on the “File” button and choosing a folder. Do this for all the tabs.

Then click “Process Job”. This creates your Gerber files.

Step 5: Adding file for drill holes

Even though drilling is supported by the Gerber format, manufacturers usually want the Excellon file format for specifying drill holes. Luckily, Eagle also comes with a predefined job for creating a drill file.

(Note: This step is automatically done if you’re using the CAM-file from Seeed Studio that I linked to in step 2.)

Open it in the CAM Processor by clicking “File->Open->Job…”

Browse to your …/eagle/cam/ folder, and open the file named “excellon.cam”.

Select where to put the output file by clicking on the “File” button.

How To Open Pcb Gerber File Download

Then click “Process Job” to create your Excellon file.

Step 6: Check output files

You should now have the following files:

- *.cmp (Copper, component side)

- *.drd (Drill file)

- *.dri (Drill Station Info File) – Usually not needed

- *.gpi (Photoplotter Info File) – Usually not needed

- *.plc (Silk screen, component side)

- *.pls (Silk screen, solder side)

- *.sol (Copper, solder side)

- *.stc (Solder stop mask, component side)

- *.sts (Solder stop mask, solder side)

After you have created each gerber file, you should always look at them using a Gerber viewer to make sure everything is ok.

Summary

This Gerber tutorial shows one way of creating the files you need. Even though this should be OK for many PCB manufacturers, you might find that some would want the files created in a slightly different way. If so, don’t worry, they will probably provide you with a Job file you can load directly into Eagle or at least have a good explanation on how to do it on their website.

Check out more articles on PCB design by clicking this link:

Return from Gerber File to PCB Design

Generating Gerbers

Select File -> Plot from the menu to open the gerber generation tool.

At the top of the pop-up window, you’ll see the folder location for your files, click browse. Make sure you’re in your project directory.

Make a new folder called Gerbers, select it and click select folder. Click Yes if asked to use a relative path.

On the left side, you’ll see which layers from our board design we want to turn into Gerber files.

Select all the layers you need. For a simple PCB, you’ll need the

- Top and Bottom silkscreen layers

- Front and back copper

- Edge cuts

The In1 and In2 layers are only needed for four-layer boards.

Make sure the front and back copper layers are checked as well as the front and back silkscreen layers. Check front mask, back mask, and edge cuts.

The mask layers show where solder mask needs to go and the edge cuts layer is our board outline with the slot cut out at the top.

It also gives us which options we need to check.

Make sure that the “Exclude PCB edge layer from other layers” is checked. We want the part reference designators to show up on the board so leave that checked. But we don’t want the values to be printed, so uncheck “Plot footprint values”.

Click 'Plot' and the Gerber files will be generated and saved in the Gerbers folder.

Generating Drill file

Click “Generate Drill File“. Check the below options and leave everything else to default.

- 'Inches'

- 'Decimal format'

- 'Postscript'

Click “Generate Drill File” and you should see a message in the bottom text window indicating that new files were created.

How To Open Pcb Gerber File Extension

Verify the Files

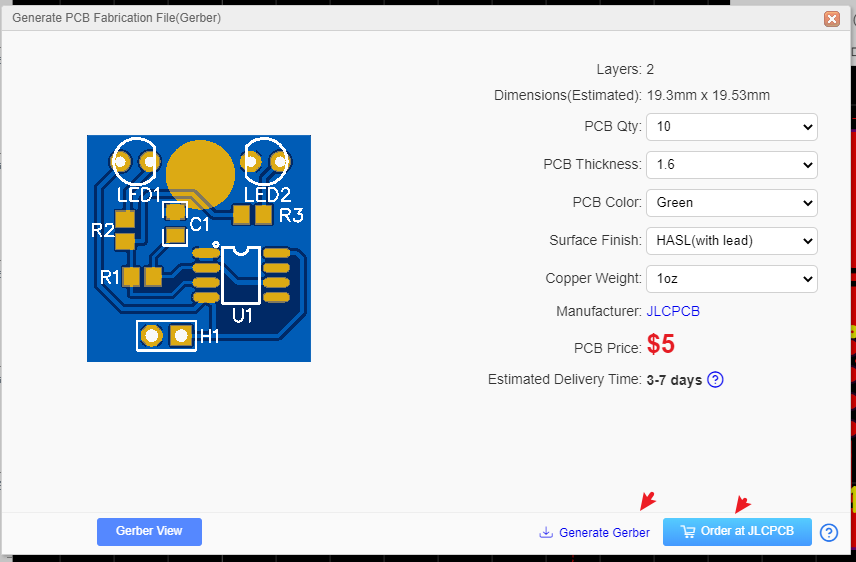

Next, click 'Close' to exit the Generate Drill File windows. All of the files should have appeared in your gerbers folder. Then select all of the files, zip them up, and upload the zip file to JLCPCB order page.

How To Open Pcb Gerber Files

After uploading your files, you can verify the gerbers by using our Gerber Viewer.